Our unoiled Hinoki and sugi products offer an ideal choice for sauna interiors. However, it’s important to note that yakisugi “shou sugi ban” charred wood products or any kind of oil finish or stain should not be specified in sauna applications. Please see our Hinoki Moulder Blank page for specification and ordering information.

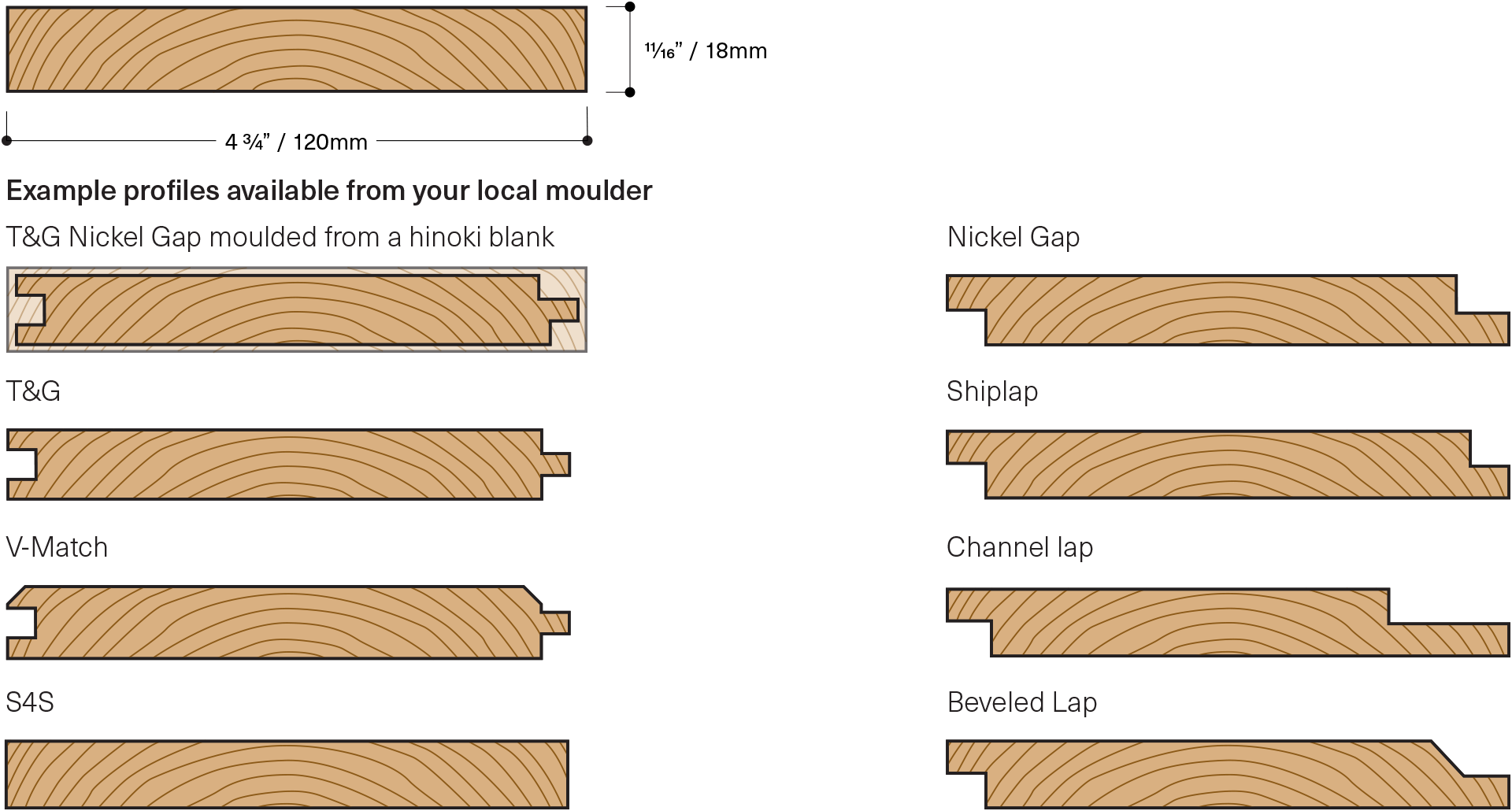

On sauna applications there are a few important parameters to follow for best results. Make sure that the lumber is under 10% moisture content before moulding and installation. Mould into a profile that allows for dramatic swelling and shrinkage without becoming noticeable. This generally means a 3/8” long tongue and groove, with a 1/4″ or so nickel gap in the profile. Acclimate the paneling stickered in the sauna itself for two weeks under normal operating conditions before installation. For best results elevate the stickered lumber on saw horses or scaffolding towards the top half of the room to expose it to the most extreme conditions. Design in a vented screen wall assembly and install with stainless steel 15gauge or larger headed nails through the tongue. Set face nails since the fasteners get very hot to the touch.

It is important to note that sauna applications are the most challenging of all installation conditions. Atmospheric conditions can vary according to room design, heater specifications, and heater operation, especially if administered by a group. In some cases, no matter how careful the millwork or installation are executed, there can still be considerable dimensional movement and sometimes failure requiring replacement.